What Will You Gain From This Article

- • General knowledge of structural steel

- • An understanding of the different ways that structural steel is connected

- • Insight into types of bolts and their installation

• An awareness of types of bolted joints used for structural steel

• Knowledge of welding terminology, weld types, and welding processes

• Familiarity with common weld inspection methods and considerations associated with field welding

Benefits of Structural Steel

Some benefits associated with the use of structural steel for owners are:

• Steel allows for reduced frame construction time and the ability to construct in all seasons

• Steel makes large spans and bay sizes possible, providing more flexibility for owners

• Steel is easier to modify and reinforce if architectural changes are made to a facility over its life

• Steel is lightweight and can reduce foundation costs

• Steel is durable, long-lasting and recyclable

Unique Aspects of Steel Construction

Procurement and management of structural steel are similar to other materials, but there are some unique aspects of steel construction:

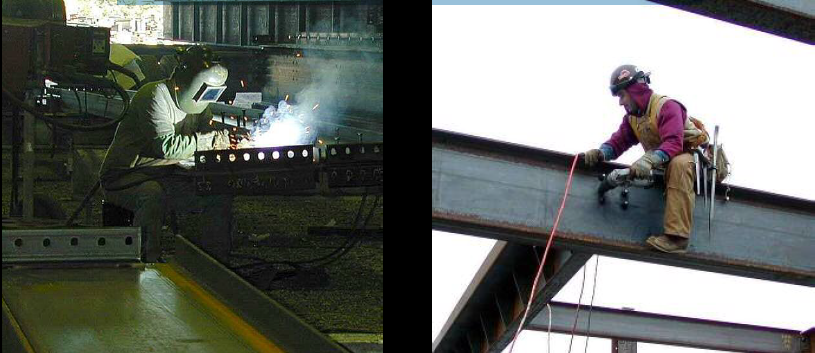

• Steel is fabricated off-site (above left)

• On-site erection is a rapid process (above right)

• This gives users of structural steel some scheduling advantages

• Coordination of all parties is essential for achieving potential advantages

Connecting Structural Steel

• The primary connection methods for structural steel are bolting and welding

• A structure’s strength depends on proper use of these connection methods

• Connections made in a fabrication shop are called shop connections

• Connections made in the field by the steel erector are called field connections

• Bolting and welding may be used for shop connections and field connections

Connecting Structural Steel

• A fabrication shop will have the desired fastening method suited to its equipment and fabrication methods

• Field connections are typically bolted

• Welding may be used for field connections where bolting is either impractical or undesirable

• Welding is better suited to the controlled environment of a fabrication shop