Commutation Definition

This is the post about commutation in dc generator and dc motor. The reversal of current in the armature winding by means of commutator bar and brushes is known as commutation process.

The necessity of Commutation In DC Machine

Commutation serves two purposes,

1. It converts alternating current to direct current

2 It maintains rotor magnetomotive force stationary in space.

The concept of Commutation in DC Machine

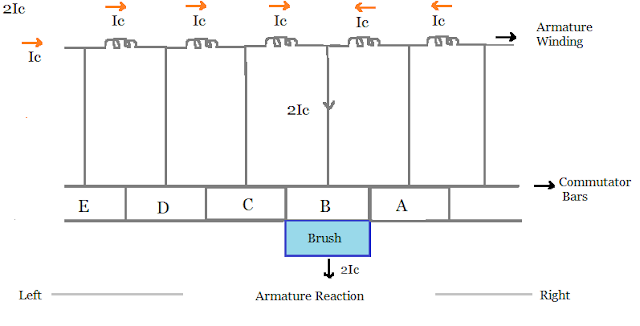

Commutation process in DC machine can be explained by assuming commutator bar width is equal to brush width and insulation between the commutator bar is of negligible thickness.

For understanding the physical concept behind the process of communication, let us consider, five instants of commutator working with respect to brushes. The armature of considered D.C, the machine is rotating from left to right.

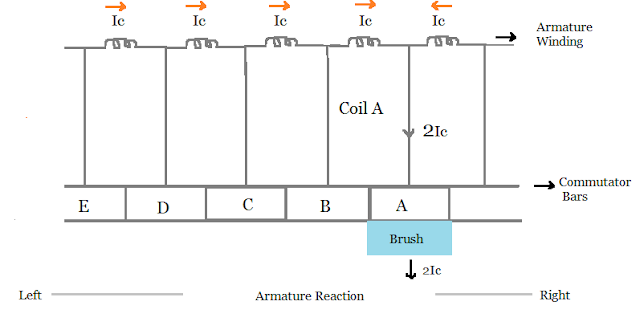

At the first instant, the brush is completely situated on commutator bar A and it is delivering 2Ic (current) current Ic flows through coil A from left to right as shown in below figure.

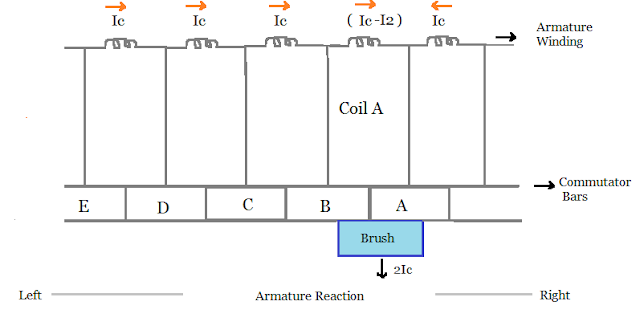

At the second instant, when the brush comes in contact’ with bar 2, coil A gets short-circuited. If the current from bar B to brush is I2 then current in coil A changes from 2Ic to (Ic — I2). In order to produce output current from the brush as 2Ic, the commutator bar delivers 2Ic — I2 current to the brush as shown in below figure.

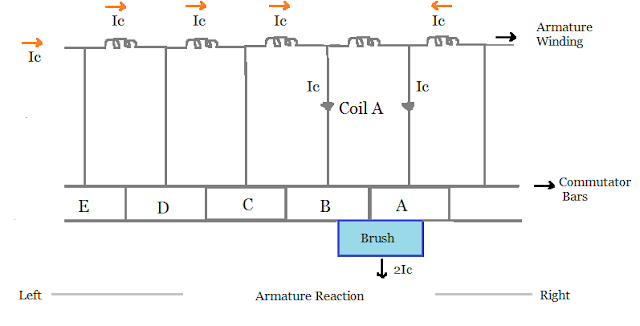

At the third instant, when the brush occupies the equal area of bar A and bar B, now coil A carries no current, bar A and bar B delivers the same amount of current Ic to the brush as shown in below figure.

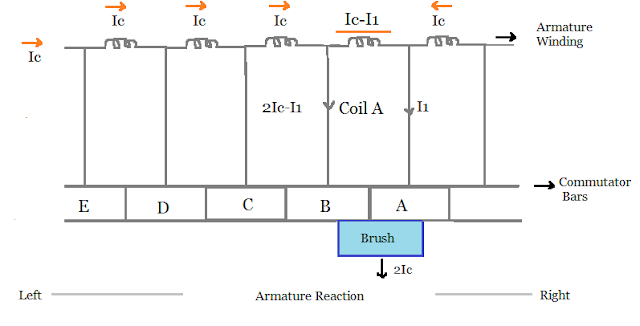

At the fourth instant, when the armature and commutator bar rotation increases, the brush occupies the large area of bar B. Area of contact between brush and bar decreases thus decreasing the current in bar A to ie., During this instant, coil A carries current Ic – I1 from right to left. Here, bar B carries (2Ic-I1) current so that brush delivers the output current of 2Ic as shown in the below figure.

At the fifth instant, when brush occupies the complete area of bar B, now the coil A is open circuited and therefore carries current from right to left as shown in below figure.

Commutation Period (Tc)

It is defined as the time taken by coil A to change current Ic from +Ic to -Ic.

Mathematically commutation period (Tc) may be defined as,

Commutation in D.C. Generator

As D.C. generator consists of two brushes and they are placed on opposite sides of commutator each brush slides along one half of commutator and then follows the other half forming a loop.

During the instant when loop reaches the point of rotation the voltage induced reverses the polarity, the brush shifts from one commutator segment of other therefore indicating that one brush is positive with respect to others. The voltage between the brushes fluctuates in amplitude between ‘0’ and maximum value.

Commutation in D.C. Motor

The process of commutation in DC. the motor is same as DC. generator but the only difference is the power is transferred from terminal to the armature by means of brushes and commutator.

Causes of Poor Commutation

Poor commutation is caused due to,

1. Poor mechanical conditions like uneven surface of commutators, vibrations of brushes etc.

2. Poor electrical conditions such as increased voltage between the bars of commutators, increase in the current density of brushes etc.