DC motors are of 3 types as follows

D.C.Series Motor:

Which is attached to the field with a field coil armature in DC motors, it is called a series motor. Its field coil is made of a low-angle thick wire. Such motors are very high work in the starting.

When changes in armament currents are changed in such motors, flux changes also. In other words, the load decreases with speed as much as it grows. Similarly, when the load decreases, the reduction in currents And increase in the back emf. The increase in the speed of the emf should also increase its speed and the increase in the speed in the speed of this is in the root ratio. Whenever there is a load of 0, the speed of the motor increases so much so that the winding out of the armature also removes the winding from its center reclamation force. Therefore, when the serial motor is loaded on load 0 or executed with very little load Do not come.

According to the above, when the load is moved in a snap, the speed of the motor increases very rapidly due to the decrease of the flux. For this reason, connecting this motor with a bandage is a danger. Because if the belt breaks or slips then the speed will increase very fast.

Series motor used:

It is used where there is a need for more torque at the beginning of the place eg Cracken, Hause, Electric Train, and Tram, Large Bending Roll, Fan, Air Compressor, Gear Drive etc.

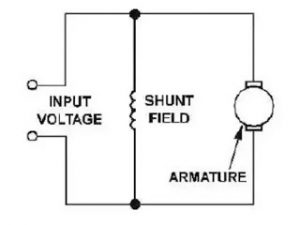

2.DC Shunt Motor:

In this type of motor, the field coil and armature are connected in parallel to each other. To make the field of this motor more barrier, it is made to make the wire more intense, making it coiled with a wire. Since the field was in parallel to the field winding armature The same electrical current flows from the field

When the load is zero, the flux is high. And as the load increases. As per the reaction of Arthritis, there is the slight change in this flux. Changes in speed due to changes in flux, but this change is minimal Due to this reason the shunt motor is called a continuous motor.

Specifically, each shin motor with a capacity of 1/2 hp or higher has additional poles between its main poles. Their cues are to prevent sparking. This motor can be converted into a reverse direction and can be changed in the opposite direction. It has to change the direction of current flowing through the armature.

Use of shunt motor:

Since the shunt motor has a feature of motionless motion, this type of motor is used to run the space which is not allowed to change the speed of the motions, as the introduction of the machine shaft line shaft, as well as running pumps, machine tools, bloilers, printing presses, spinning machines etc. For this type of motor is used.

3. Compound Motor:

Like a compound generator, compound motor also has field coils both in the series and shunt, and so the flux that is produced inside the air gap is caused by the combined effect of both the fields, the series is composed of a low-thick thick wire, whereas shunt vibrating increases This type of motor has both a series of shirts and shirt type, both types of compound motor If the series field is dominant then the motor series will act like a motor and if the shunt field is dominant then the motor shirt will work like a motor.

If both of these field’s flux is in one direction, both of these fields are connected, then a combination motor is called a computational compound motor but if the series field is in the opposite direction of the flux shunt field of the field then the connection motor should be replaced by the differential comp motor Is called

Use of Compound Motor:

This type of motor is used in the motor, for example, to see the properties of both the series and shunt in Malta, where there is a need for excessive talk breaks, eg, in the express machine, rolling mills, stone crush lift etc.

Advantages of a Command Motor:

1.When the load goes down, the speed of the motor does not grow much like the motor

2. If the load is high then in that case, it can produce torque in greater proportion